Cost per order (CPO)

Cost per order measures the average total cost incurred by a business to provide goods to a customer.

What is cost per order (CPO)?

Cost per order (CPO) is a key performance indicator (KPI) measuring the average total cost to a business of selling and fulfilling a single order.

This metric takes into consideration all associated costs, from advertising to warehousing to packaging. It’s often used in eCommerce, retail, and logistics to evaluate how profitable a company is and how efficient its marketing and operations are. Tracking CPO can also guide decisions on pricing.

A low CPO indicates that your business is achieving sales at a relatively low cost, which often translates to healthy profit margins. A high CPO may suggest you need to optimize your marketing efforts or cut costs to stay profitable.

How to calculate cost per order

When calculating CPO, consider both direct and indirect costs to get an accurate picture of the total price of doing business. Here are some costs you should factor in.

Direct costs

- Product costs: The cost of goods sold (COGS), including raw materials and labor.

- Shipping costs: The cost of transporting the product to the customer, including fuel, labor, and equipment.

- Packaging costs: The cost of packaging materials, such as boxes, bags, or wrapping paper.

- Handling costs: The cost of handling and processing the order, including labor and equipment costs.

- Fulfillment costs: The cost of fulfilling the order, including labor, equipment, and supplies.

Indirect costs

- Research and development costs: The cost of developing new products or services, including research, design, and testing expenses.

- Overhead costs: The cost of overhead expenses, such as rent, utilities, and insurance for your business.

- Marketing and advertising costs: The cost of promoting the product or service, including advertising, marketing, and promotional expenses.

- Order management costs: The cost of managing orders, including software and equipment.

- Inventory holding costs: The cost of holding inventory, including storage, handling, and maintenance costs.

- Customer service costs: The cost of providing customer service, including phone, email, and chat support.

- Warranty costs: The cost of warranty claims, including labor, parts, and shipping costs.

- Returns processing costs: The cost of processing returns, including labor, shipping, and handling costs.

To calculate your cost per order, you’ll need to add up all these direct and indirect costs and divide the total by the number of orders processed. This will give you a comprehensive picture of how much each order truly costs.

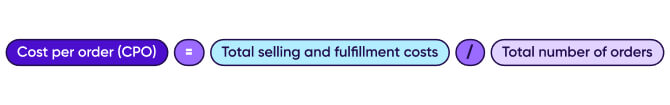

Cost per order formula

To calculate cost per order, you can use the following formula.

For example, if your total costs for a month are $10,000 and you processed 1,000 orders, your cost per order would be:

Cost per order example

Let’s say you have an online store that sells kitchen gadgets and utensils, and your average order value is $85. You received 300 orders last month and your total monthly expenses were $19,200. When you break down all the associated costs, you can see the granular cost of each order.

Direct costs

- Product cost: $12

- Shipping cost: $5

- Packaging cost: $2

- Handling cost: $2

- Fulfillment cost: $3

Total direct cost: $24

Indirect costs

- Labor cost: $10

- Overhead cost: $5

- Inventory holding cost: $2

- Order management cost: $3

- Customer service cost: $2

- Returns processing cost: $1

- Warranty cost: $1

- Marketing and advertising cost: $5

- Research and development cost: $2

- Administrative cost: $5

Total indirect cost: $40

Total cost per order = ($19,200 / 300) = $64

In this scenario, you can see the business is making a profit: The store earned $6,300 more than it spent in a month. To lower your CPO, and further increase profits, you could look through each line item of cost to find room for savings and try to raise the number of orders. While direct costs multiply with each order, many indirect costs stay flat, bringing the cost per order down with increased sales.

Advantages of using cost per order

CPO provides a bird’s eye view of your business profitability and the actual cost of selling and fulfilling an order. Overall, using CPO as a key metric helps businesses optimize their operations, improve profitability, and make data-driven decisions to drive growth. Let’s look at the advantages in more detail:

1. Identifies areas for cost reduction

By tracking CPO, you can identify areas to reduce or optimize cost, paving the way for higher profits.

2. Supports data-driven decision making

Using CPO as a KPI enables you to make data-driven decisions about pricing, marketing, and operational strategies.

3. Compare profitability between channels

When you segment out your CPO by marketing or sales channel, you can identify which channels are the most profitable. For instance, some channels may have higher acquisition costs than others and some may have a higher rate of returns.

4. Encourages efficiency and productivity

Understanding your CPO helps you focus on streamlining processes and improving productivity, resulting in lower costs and higher profitability.

5. Helps with budgeting and forecasting

Measuring CPO helps you predict your future costs and revenue, making it easier to create accurate budgets and forecasts.

6. Improve customer lifetime value

When you track CPO, you can identify opportunities to increase the average order value through loyalty programs, upselling, and cross-selling. By focusing on customer needs and satisfaction, you’ll generate repeat orders and referrals, increasing retention and lifetime value.

7. Improves supply chain optimization

CPO highlights areas where supply chain inefficiencies are impacting profitability, so you can optimize your logistics and inventory management.

Cost per order vs. alternative metrics

CPO is useful in helping you understand costs in relation to sales, but it isn’t the only metric you should look at. Consider these alternative metrics which, alongside CPO, can enhance your understanding of your eCommerce business.

CPA (cost per acquisition)

CPA measures the cost of acquiring a first-time customer, primarily through marketing and advertising. It’s closely related to CPO because it measures profitability correlated to sales. However, CPO gives a much fuller picture that includes COGS, fulfillment, and repeat purchases.

CPC (cost per click)

CPC is the cost of each individual click on an ad, regardless of whether or not it leads to a purchase. Use CPC to gauge how effective a campaign is at driving interest in a product, or as a bidding strategy for digital advertising.

CPL (cost per lead)

CPL measures the average cost of generating one lead in your pipeline. For example, if you spend $50 on advertising and generate 10 leads, your CPL would be $5 per lead. This helps you assess how expensive your lead acquisition is and which channels are most cost-effective.

CPS (cost per sale)

CPO and CPS are closely related. CPS measures the total cost of acquiring each order, but does not include direct product costs or shipping and fulfillment costs. This metric tells you more about your marketing efficiency than it does about your operations.

Tips to reduce your cost per order

Once you know your CPO, it’s time to start optimizing. There are two general strategies for optimizing CPO: lowering costs and increasing orders. Try these seven tactics to accomplish both.

1. Optimize your marketing efforts

If you’re tracking marketing metrics like CPC and CPL, you can pinpoint which marketing channels are more cost-efficient than others.

Let’s say you ran paid ads on Facebook, Instagram, and LinkedIn for the same campaign. Facebook cost $1 per click, Instagram cost $1.50 per click, and LinkedIn cost $3.50 per click. You may consider diverting funds from LinkedIn to Facebook and Instagram to optimize your spend, unless you can prove that the LinkedIn clicks resulted in more sales.

To go a step further, use attribution to understand which marketing campaigns and channels are actually leading to purchases, then increase your investment in them. For instance, you might run a Google Ads campaign for multiple keywords. If your analytics show that the more expensive keywords are resulting in more sales, it’s a good idea to continue running them.

2. Increase average order value

Consider using personalized product recommendations, upselling, and cross-selling to encourage customers to buy more with each purchase. You can also offer subscription services and free shipping or exclusive discounts to customers who make a purchase above a certain amount. The higher your average order value is, the more you’ll optimize costs like shipping and overhead.

3. Remarketing campaigns

Remarketing campaigns encourage users to re-engage with a brand or app. You could focus on customers who looked at an app or website but never made a purchase, or customers who once made a purchase and are now inactive.

These customers are more likely to engage than a person who’s hearing about your product for the first time, making it more cost-effective. Technology like programmatic advertising enables companies to nudge inactive users across multiple touchpoints, like web and mobile.

4. Process orders faster

Slow order processing can add up to higher costs for a business, like longer warehousing and rush fees for expedited shipping. To avoid this, implement a streamlined order processing system to reduce manual errors and increase efficiency. Invest in staff training, and explore ways to automate tasks such as order processing and inventory management.

5. Lower shipping costs

Shipping makes up 88% of eCommerce fulfillment costs in the US, so lowering it can make a big impact. Start by negotiating with shipping providers to get better rates for your business, or consider using third-party logistics providers to reduce costs. Use the most cost-effective shipping options for each order.

6. Reduce packaging costs

While packaging represents a smaller proportion of costs, every little bit still counts. Implement a packaging optimization strategy to reduce the amount of packaging used for each order. Consider using refillable or reusable packaging options to reduce waste and save money.

7. Automate tasks wherever possible

Look at automation options to streamline your operations, save time, and reduce cost. Examples of business automation include:

- A customer relationship management (CRM) system and marketing automation software to streamline sales and marketing

- A chatbot for common customer service queries

- An automated inventory management system to track inventory levels, alert you when items are running low, and automatically update your website

Key takeaways

Tracking CPO gives a comprehensive picture of how much each order truly costs your business. With this knowledge, you can identify areas to reduce or optimize costs, paving the way for higher profits.

- A low CPO means your business is achieving sales at a relatively low cost, while a high CPO can be a sign of inefficiencies or high costs.

- To calculate your CPO, add up all the direct and indirect costs of fulfilling one order. Then, divide that by the total number of orders you completed.

- For a fuller picture of business health, track CPO in conjunction with related metrics, like CPA, CPC, CPL, and CPS.

- Understanding CPO helps you make data-driven decisions for a more efficient and profitable business. This includes identifying ways to reduce costs, increase customer lifetime value, and optimize marketing channels and logistics.

- To reduce CPO, look to increase average order value and reduce costs. Strategies include optimizing marketing efforts, increasing average order value, running remarketing campaigns, processing orders faster, lowering shipping costs, reducing packaging costs, and automating tasks wherever possible.